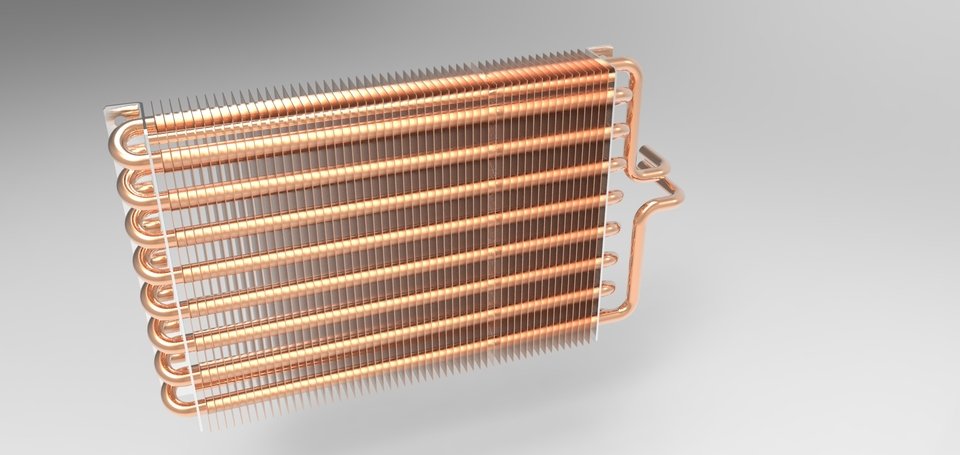

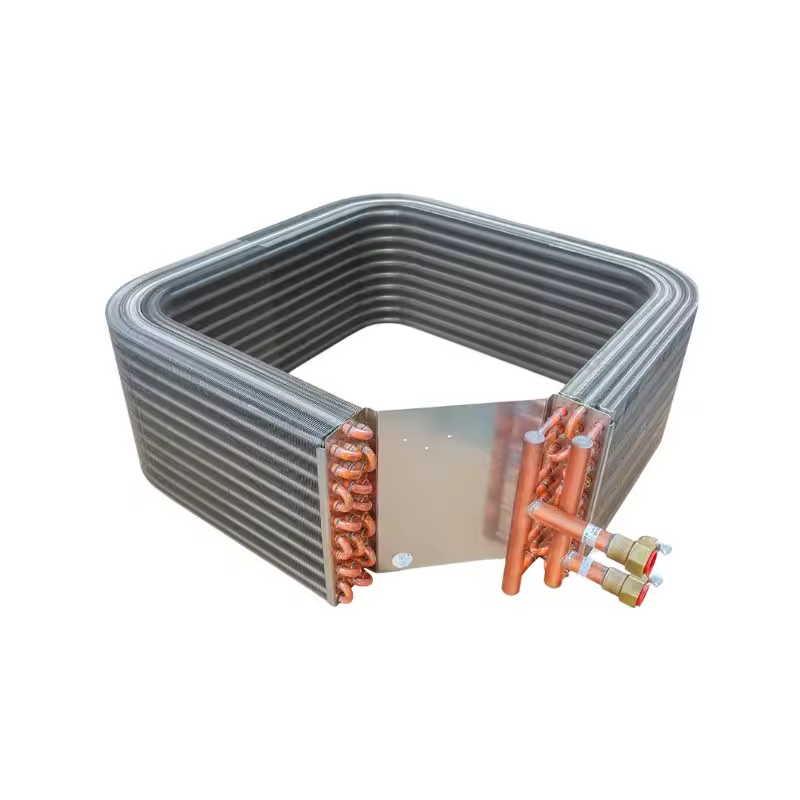

Copper & Aluminum Heat ExchangerS

Gas Copper & Aluminum Heat Exchanger

The Gas Copper & Aluminum Heat Exchanger combines the superior conductivity of copper tubing with lightweight aluminum fins, ensuring efficient heat exchange while keeping weight and cost optimized. This hybrid design is commonly used in gas water heaters, wall-hung boilers, and HVAC applications where high performance and compact size are essential

Why Gas Copper & Aluminum Heat Exchanger

Gas copper & aluminum heat exchangers combine the best of both worlds — copper tubes ensure rapid heat transfer and unmatched durability, while aluminum fins maximize surface area for faster, more efficient heating. Their lightweight and compact design makes them perfect for today’s modern wall-mounted boilers, delivering powerful performance without taking up space. With high efficiency that lowers energy bills and reduces environmental impact, these exchangers bring sustainability and savings together. Rigorously tested under continuous heating cycles, they guarantee long-lasting reliability, making them the trusted choice for modern gas heating systems.

Comparison and Modern Relevance

The Gas Copper & Aluminum Heat Exchanger is engineered for high-performance heating systems, combining the unmatched thermal conductivity of copper tubes with the lightweight efficiency of aluminum fins. This hybrid construction ensures rapid heat transfer, reduced energy loss, and extended durability, making it a trusted solution for modern gas water heaters and boilers.

Compact in design, it is suitable for wall-mounted and floor-standing boilers, offering flexibility without compromising power. Its corrosion-resistant build and rigorous reliability testing guarantee long life under continuous heating cycles. By maximizing efficiency, it reduces both operating costs and emissions, aligning with today’s demand for sustainable heating solutions.

🔧 Advanced Methods & Features

Bimetallic Integration: Copper tubes are precision-fitted with aluminum fins through mechanical expansion, ensuring strong thermal bonding for optimal heat transfer.

Corrugated Fin Technology: Aluminum fins feature a micro-corrugated surface that increases turbulence, enhances air contact, and accelerates heating efficiency.

Optimized Tube Geometry: Copper tubes are designed with thin walls and high conductivity to minimize thermal resistance.

Anti-Corrosion Coating: Advanced tin-coating or protective layering can be applied to extend service life in demanding environments.

Lightweight Engineering: Aluminum reduces weight significantly, making installation faster and reducing structural load on boilers.

Sustainability Advantage: High efficiency means lower fuel consumption, supporting eco-friendly energy standards.

What We’re Offering

Why you Should Choose Our Services

- Advanced Machinery & Automation

- Expert Technical Team

- Strict Quality & On-Time Delivery

- Complete Production Process

- Custom-Engineered Solutions

Address

Kinetix Fabworks Pvt Ltd.

Okkal Thuruthu.

Ernakulam – 683550.

Kerala, India.

Asia Pacific Regional Sales Support

North American Regional Sales Support

- © Copyright 2025 Kinetix fabworks Private Limited