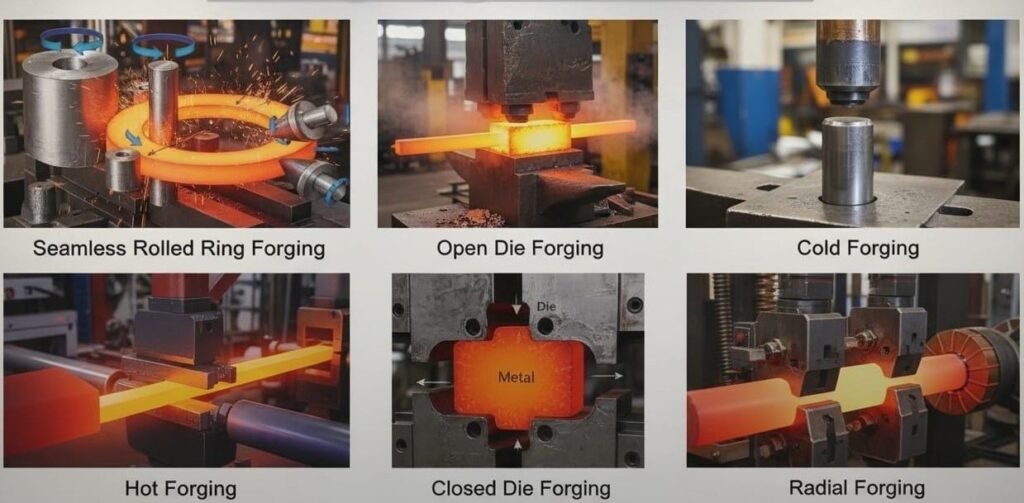

TYPES OF FORGING

- Open-Die Forging – Large components shaped by repeated blows.

- Closed-Die (Impression Die) Forging – Metal pressed into shaped dies for precise parts.

- Cold Forging – Performed at room temperature for high accuracy and finish.

Simplifying Tomorrow with Smarter Solutions.

YOUR VISION OUR TECHNOLOGY

Why Forging services

At KINETIXFAB, forging is more than shaping metal — it is about creating durable, high-performance components engineered to withstand real-world demands. Our forging services combine advanced machinery, skilled craftsmanship, and rigorous quality control to deliver products that meet international standards for strength, accuracy, and reliability. We provide custom-forged solutions for automotive, construction, agriculture, and industrial applications, ensuring that every piece is optimized for long-term use and heavy-duty performance. By choosing our forging services, businesses gain access to components that are tougher, more cost-effective, and designed for global competitiveness.

Forging is a manufacturing process that shapes metal using compressive forces. By hammering, pressing, or rolling heated or cold metal, forging improves its strength, toughness, and durability. It is widely used in automotive, aerospace, construction, and machinery industries to produce high-performance parts with superior mechanical properties.

Core Advantages

- Consistent strength and durability for critical parts

- Tailored forging solutions for multi-industry applications

- Export-ready quality with international compliance

- Cost-efficient manufacturing with high-volume capacity

★ Specialized Services

- Precision Cutting

• Laser and orbital cutting for burr-free edges and tight tolerance assemblies Complex Bending

• Advanced simulation and feedback systems ensure repeatable accuracy in high-stress applicationsEnd Forming

• Techniques include expansion, reduction, swaging, and flaring for engineered joining featuresAssembly & Welding

• High-strength TIG, MIG, and robotic welding with microstructural stabilitySurface Engineering

• Passivation, polishing, and coating treatments for corrosion resistance and extended service life

★ Engineering Dimensions

- Geometric Control

• CNC systems regulate bend radii, wall thinning, and neutral axis shifts

• Supports multi-plane configurations without structural compromise Metallurgical Integrity

• Heat treatments and forming parameters preserve grain structure, toughness, and fatigue resistanceStructural Adaptability

• End forming and welding enable seamless integration into HVAC, automotive, and aerospace systems

• Adapts to complex design geometries

Address

Kinetix Fabworks Pvt Ltd.

Okkal Thuruthu.

Ernakulam – 683550.

Kerala, India.

Asia Pacific Regional Sales Support

North American Regional Sales Support

- © Copyright 2025 Kinetix fabworks Private Limited