High-Accuracy Components for Every Industry

Engineering with CNC Machining. Smart, Scalable Fabrication for Every Industry.

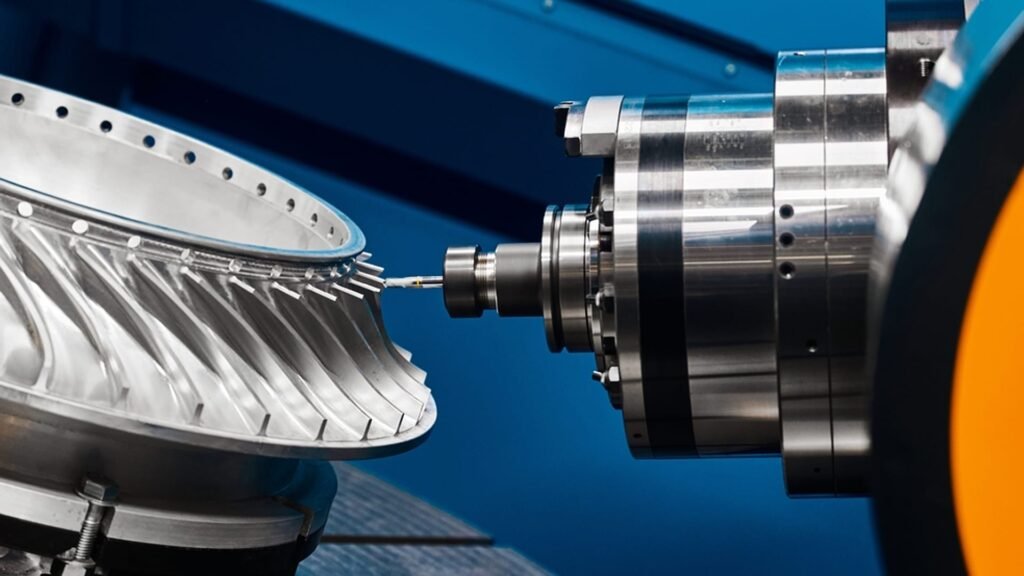

Our CNC Machining services deliver unmatched precision and repeatability for complex parts and tight tolerances. Powered by advanced software and skilled operators, we shape metals and materials into flawless components for aerospace, automotive, medical, and industrial applications. Whether it’s prototyping or mass production, we ensure every cut counts

Your Fabrication Partner for Quality, Speed, and Consistency

Why CNC Machining Services

Industries demanding repeatable precision, intricate features, and structural reliability rely on CNC machining. At Kinetix Fabworks, CAD/CAM integration, simulation-based process optimization, and adaptive cutting parameters minimize tool wear, improve surface integrity, and reduce cycle times. These practices ensure both prototype and series production components meet rigorous aerospace, automotive, and industrial standards.

Precision Material Removal

⚙️ CNC Milling

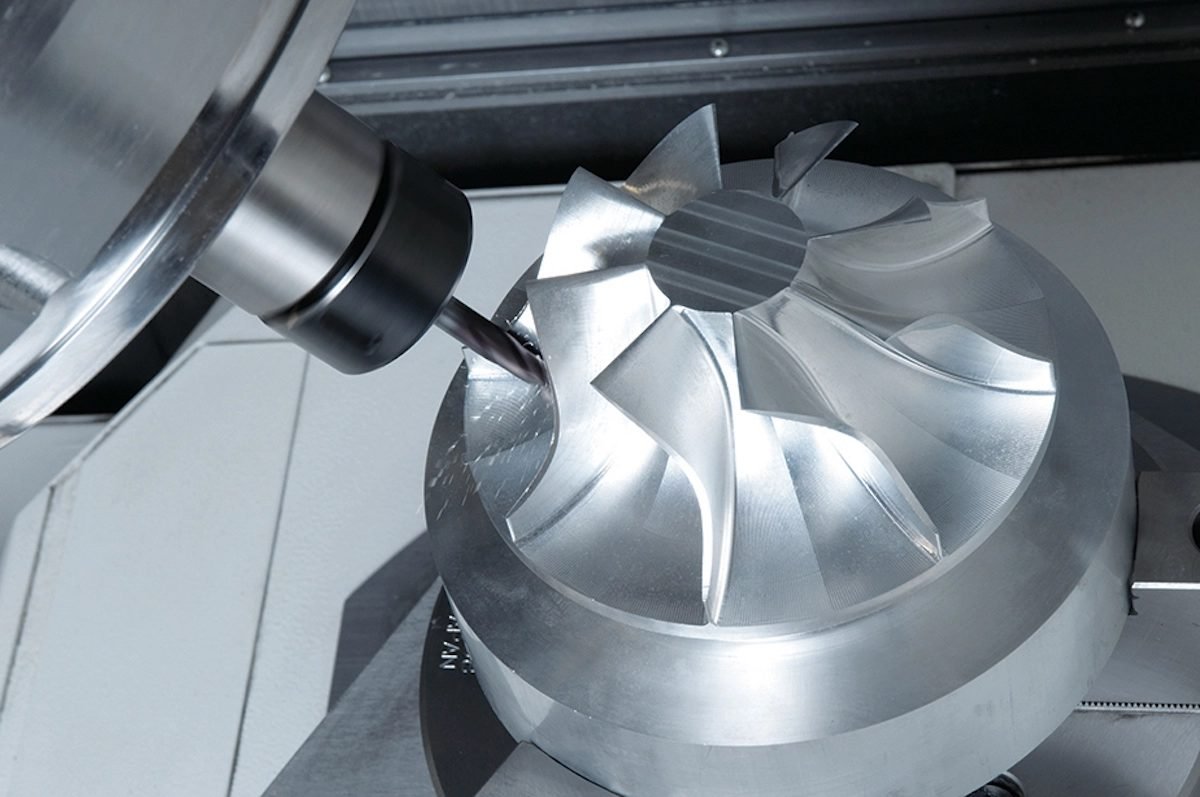

Multi-axis milling produces prismatic and contoured geometries, complex pockets, and intersecting features with optimized tool engagement and minimal thermal distortion.

⚙️ CNC Turning

Sub-spindle and live tooling allow precise bores, threads, and profiles with controlled surface roughness (Ra) and concentricity.

⚙️ Swiss & Micro Machining

Sliding-headstock and sub-millimeter tooling generate high aspect-ratio micro-parts with burr-free edges for electronics, medical, and precision components.

⚙️ Hybrid Operations

Milling, turning, and drilling combined in a single setup reduce handling errors, maintain tolerances, and accelerate multi-feature part production.

Surface Integrity & Validation

⚙️ Grinding & Secondary Finishing

Cylindrical and surface grinding, lapping, and polishing deliver sub-micron finishes, enhance fatigue resistance, and improve edge geometry.

⚙️ Deburring & Edge Conditioning

Mechanical and automated deburring remove micro-burrs, preserve tolerances, and prevent assembly interference.

⚙️ Metrology & Dimensional Verification

CMM, laser scanning, and optical measurement systems ensure parts meet geometric and tolerance specifications.

⚙️ Material & Performance Testing

Hardness testing, surface profilometry, and microstructure analysis verify mechanical properties and structural integrity under operational loads.

CNC Machining

Computer Numerical Control (CNC) machining transforms raw metallic and polymeric stock into precision-engineered components with high geometric fidelity. Multi-axis milling, turning, and drilling operations allow production of complex prismatic and freeform features, tight tolerances, and consistent surface finishes. Kinetix Fabworks leverages adaptive toolpath strategies, kinematic control, and real-time spindle monitoring to achieve micron-level accuracy while preserving material properties.

Specialized Services

Precision Cutting

• Laser and orbital cutting for burr-free edges and tight tolerance assembliesComplex Bending

• Advanced simulation and feedback systems ensure repeatable accuracy in high-stress applicationsEnd Forming

• Techniques include expansion, reduction, swaging, and flaring for engineered joining featuresAssembly & Welding

• High-strength TIG, MIG, and robotic welding with microstructural stabilitySurface Engineering

• Passivation, polishing, and coating treatments for corrosion resistance and extended service life

Engineering solutions

Geometric Control

• CNC systems regulate bend radii, wall thinning, and neutral axis shifts

• Supports multi-plane configurations without structural compromiseMetallurgical Integrity

• Heat treatments and forming parameters preserve grain structure, toughness, and fatigue resistanceStructural Adaptability

• End forming and welding enable seamless integration into HVAC, automotive, and aerospace systems

• Adapts to complex design geometries

CNC milling is widely used across sectors such as aerospace, automotive, defense, energy, electronics, and medical device manufacturing. It supports a wide range of materials including aluminum, steel, titanium, copper, polymers, and composite materials. With capabilities for prototyping, small-batch runs, and mass production, CNC milling is valued for its:

High Precision & Accuracy: Capable of achieving tolerances within microns.

Complex Geometry Production: Enables creation of intricate parts impossible with conventional machining.

Efficiency & Automation: Continuous operation with minimal human intervention.

Surface Finish & Consistency: Produces smooth finishes and repeatable quality.

Flexibility: Easily programmable for different designs and product variations.

Address

Kinetix Fabworks Pvt Ltd.

Okkal Thuruthu.

Ernakulam – 683550.

Kerala, India.

Asia Pacific Regional Sales Support

North American Regional Sales Support

- © Copyright 2025 Kinetix fabworks Private Limited