Tube End Forming for Seamless Fit and Function.

Custom End Forming Solutions for Automotive, HVAC, and Industrial Applications

Engineering Solutions That Shape Your Success

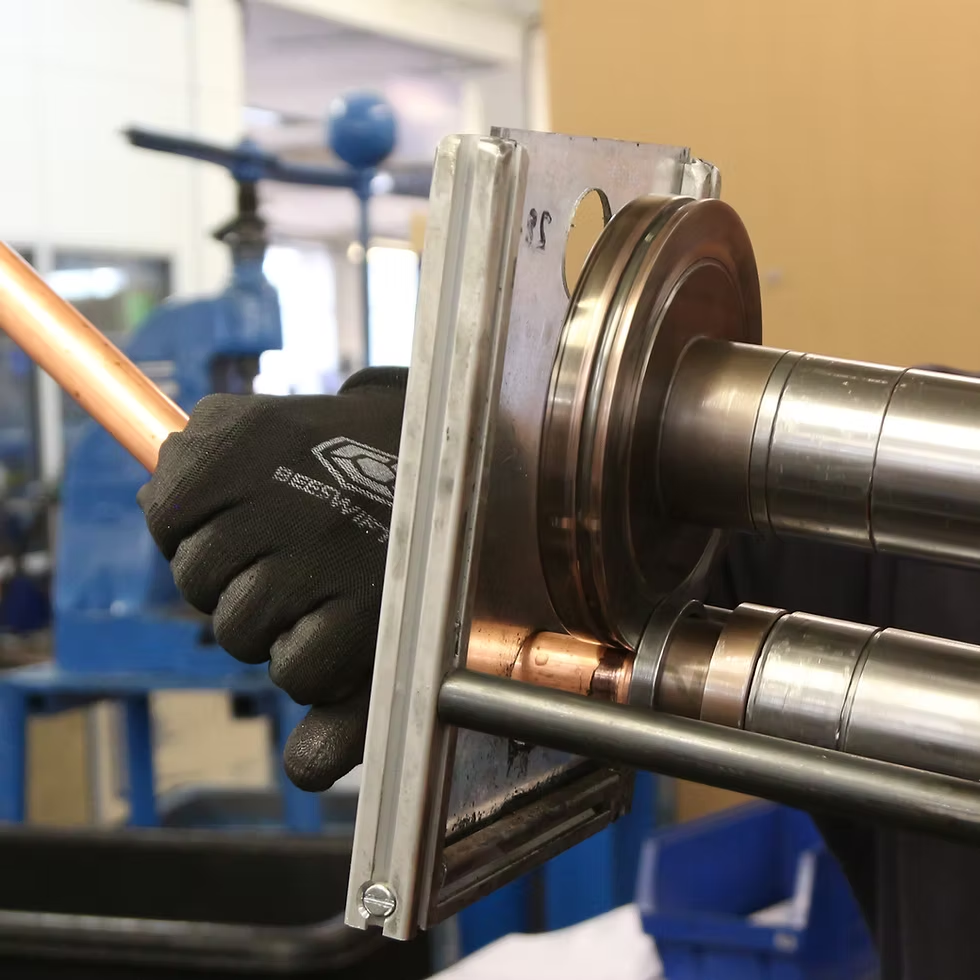

End forming is a specialized process used to shape the ends of tubes for precise fitment, improved sealing, and optimized flow. Whether it’s flaring, beading, expanding, or reducing, our CNC-controlled machines deliver consistent results across all materials and geometries. Ideal for exhaust systems, fluid lines, and structural assemblies, our end forming services ensure your components meet exact specifications with zero compromise on quality.

We offer both ram and segmented tooling options to suit your project’s needs—whether it’s high-volume production or custom prototyping.

Smart Fabrication for Real-World Demands

Why End Forming Services

Applications requiring leak-proof sealing, mechanical retention, and fluid-dynamic optimization depend on advanced end forming techniques. At Kinetix Fabworks, CNC-controlled end forming machines combine servo-driven force application with adaptive tooling alignment to achieve repeatable geometry, minimal ovality, and strain-balanced walls. This ensures reliable performance under high pressure, vibration, and thermal cycling conditions, reducing assembly failures and extending component lifespan.

Forming & Shaping Dynamics

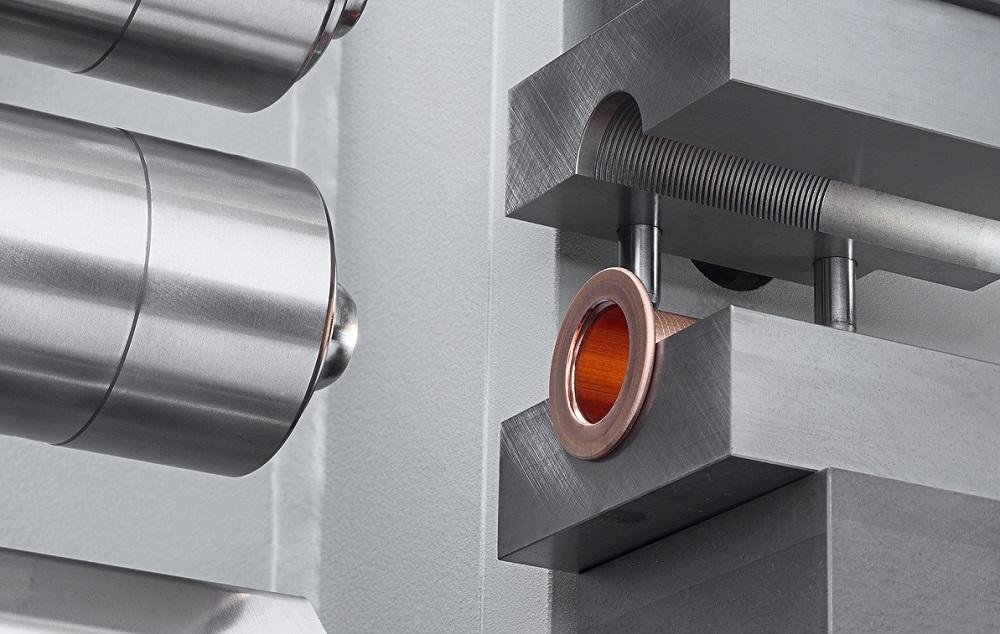

⚙️ Flaring

Axial expansion of tube ends produces conical or bell-shaped profiles, enabling secure connections for hydraulic fittings and high-pressure seals.

⚙️ Swaging

Diameter reduction through compressive dies creates step transitions and allows for precise interfacing with mating parts while maintaining concentricity.

⚙️ Beading

Radial displacement forms circumferential ridges that act as mechanical locks for hoses, clamps, and flexible couplings in fluid systems.

⚙️ Tapering

Gradual reduction of tube wall diameter enhances flow entry, aerodynamic efficiency, and integration into convergent system geometries.

Precision Control & Validation

⚙️ Rotary End Forming

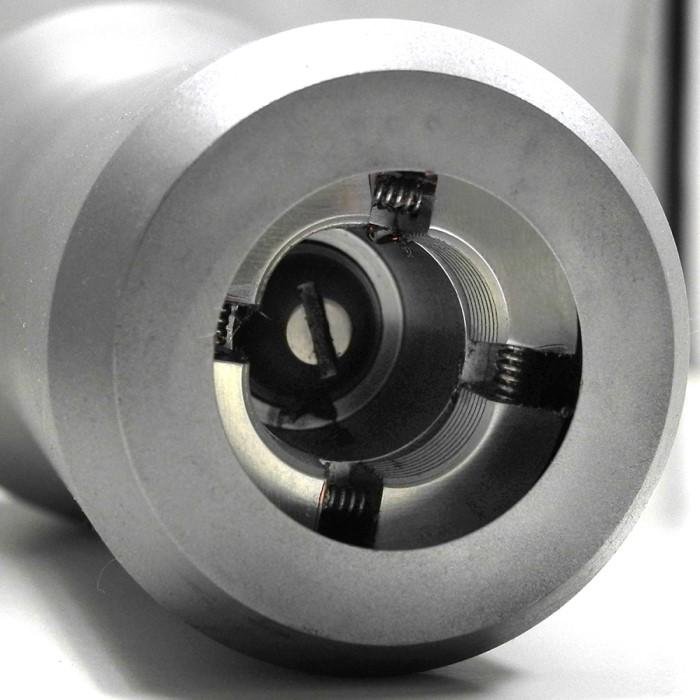

Rotational die systems distribute forming stresses evenly, minimizing thinning and enabling complex, multi-stage end geometries.

⚙️ Adaptive Tooling Systems

Servo-driven dies and modular mandrels accommodate multiple diameters and wall thicknesses, ensuring repeatability and flexible production.

⚙️ Surface Conditioning

Post-forming deburring, polishing, and stress relief treatments improve fatigue resistance and prevent crack initiation at deformation zones.

⚙️ Inspection & Quality Verification

Dimensional metrology, ovality checks, and pressure/leak testing validate end geometry against aerospace, automotive, and energy-sector specifications.

Controlled deformation of tube ends is essential for preparing joints, sealing interfaces, and flow-optimized geometries in engineered assemblies. End forming processes apply axial and radial force under precision tooling to alter the tube’s terminal geometry without compromising wall integrity. These methods create functional transitions such as flares, beads, swages, or tapers, enabling tubes to integrate seamlessly into mechanical, fluid, and thermal systems across demanding industries.

Tube end forming is an advanced fabrication process that reshapes the terminal section of tubes into engineered profiles through axial compression, controlled expansion, or radial displacement. The method is essential for creating high-performance connections in HVAC, automotive, aerospace, and fluid transport systems, where both dimensional precision and sealing efficiency are critical.

The efficiency of end forming lies in its ability to:

Enhance Joint Integrity: Expanded or reduced ends allow tighter fittings, eliminating leakage and improving reliability.

Optimize Flow Dynamics: Smooth flaring and flanging reduce turbulence, improving system efficiency in HVAC and fluid networks.

Reduce Secondary Operations: Net-shape forming minimizes welding, machining, and finishing requirements, lowering cost and production time.

Maintain Structural Stability: Properly calibrated forming avoids thinning, wrinkling, or stress concentration, ensuring long service life.

Kinetix Fabworks employs CNC and hydraulic forming systems to deliver repeatable accuracy, with process parameters optimized to control wall thickness, bend radius, and strain distribution. The integration of real-time monitoring ensures consistent quality and eliminates variability, even in complex geometries.

Efficiency is further enhanced through tooling innovation and thermomechanical control. By applying forming under carefully managed temperature and load conditions, we reduce forming forces, extend tool life, and improve surface finish.

At Kinetix Fabworks, tube end forming is not just a shaping technique—it is an engineering-driven solution that combines scientific precision with industrial efficiency, enabling stronger, cleaner, and more reliable assemblies across industries.

Address

Kinetix Fabworks Pvt Ltd.

Okkal Thuruthu.

Ernakulam – 683550.

Kerala, India.

Asia Pacific Regional Sales Support

North American Regional Sales Support

- © Copyright 2025 Kinetix fabworks Private Limited