Services

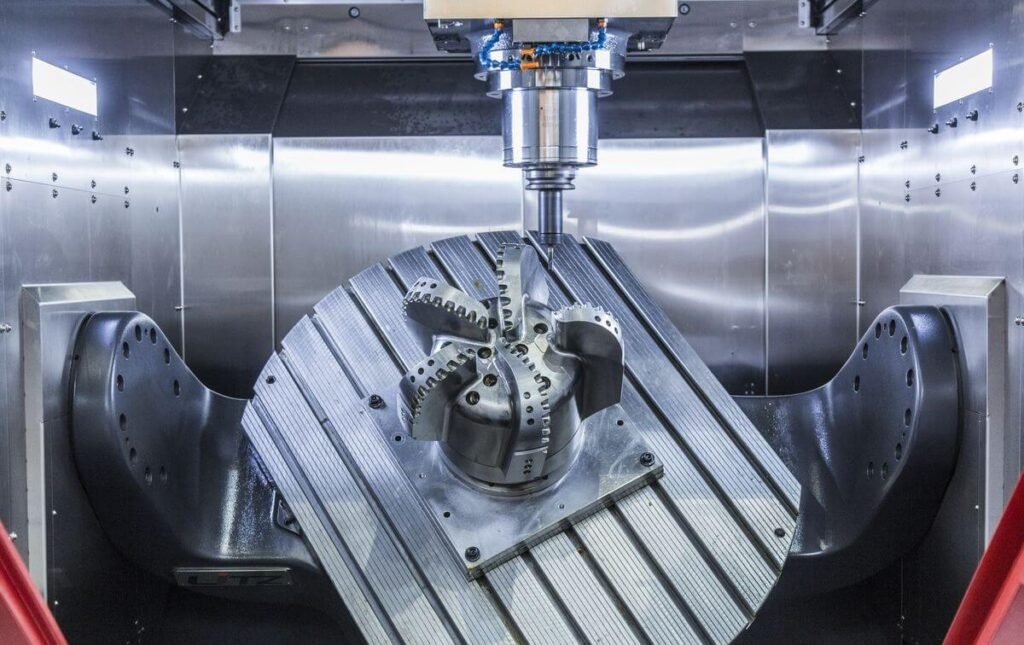

5 Axis Machining

5-axis machining is an advanced subtractive manufacturing process where a computer-controlled cutting tool or workpiece moves simultaneously along five independent axes (X, Y, Z, A, and B). Unlike conventional 3-axis machining, this multidimensional motion enables complex geometries, undercuts, and freeform surfaces to be produced with exceptional precision and reduced setups. The process integrates CAD/CAM-generated toolpaths with servo-driven kinematics, allowing continuous angular orientation of the cutting tool relative to the workpiece. This eliminates repositioning errors, optimizes chip load distribution, and enhances tool life, while maintaining sub-micron accuracy.

Progress Engineered Through Data and Dynamics

Vision Powered by Intelligent Systems

Why 5-Axis Machining Services

Components requiring complex 3D geometries, high-precision features, and reduced setup times rely on 5-axis machining. At Kinetix Fabworks, multi-axis toolpath simulation, adaptive spindle control, and collision avoidance algorithms guarantee minimal tool deflection, superior surface integrity, and precise feature replication. This process reduces production time, lowers secondary operations, and produces parts ready for immediate assembly in critical applications.

Multi-Axis Material Removal

⚙️ Simultaneous 5-Axis Milling

High-speed simultaneous movement of X, Y, Z, A, and B axes enables production of sculpted surfaces, deep cavities, and complex contours with micron-level accuracy.

⚙️ Dynamic Toolpath Optimization

Adaptive motion strategies adjust cutting speed, feed rate, and tool orientation in real time to minimize vibration, chatter, and residual stress.

⚙️ Rotary & Tilting Table Integration

Rotary and tilting table setups allow angular access to features without multiple setups, reducing repositioning errors and ensuring geometric consistency.

⚙️ Hybrid Machining Operations

Combining milling, drilling, and tapping in a single setup reduces handling, maintains precision, and accelerates the production of multi-feature components.

Surface Quality & Verification

⚙️ High-Precision Surface Finishing

Controlled spindle dynamics and optimized cutting paths achieve fine surface roughness (Ra) and prevent micro-cracks or thermal distortion.

⚙️ Deburring & Edge Refinement

Automated and mechanical deburring techniques remove burrs, improve fatigue resistance, and maintain precise edge geometry.

⚙️ Coordinate Metrology & Inspection

CMM and laser scanning validate complex geometries, surface profiles, and angular tolerances to ensure full compliance with design specifications.

⚙️ Material Integrity Testing

Hardness testing, microstructure analysis, and residual stress evaluation confirm part performance under operational loads and thermomechanical conditions.

Specialized Services

Precision Cutting

• Laser and orbital cutting for burr-free edges and tight tolerance assembliesComplex Bending

• Advanced simulation and feedback systems ensure repeatable accuracy in high-stress applicationsEnd Forming

• Techniques include expansion, reduction, swaging, and flaring for engineered joining featuresAssembly & Welding

• High-strength TIG, MIG, and robotic welding with microstructural stabilitySurface Engineering

• Passivation, polishing, and coating treatments for corrosion resistance and extended service life

5-Axis Machining

Advanced 5-axis CNC machining enables simultaneous motion along multiple axes, producing complex geometries that would be impossible with traditional 3-axis systems. This technology allows intricate contours, deep cavities, and compound angles while maintaining tight tolerances, consistent surface finish, and high structural integrity. Kinematic synchronization, dynamic toolpath optimization, and thermal compensation ensure accurate, repeatable results for aerospace, automotive, and precision engineering components.

Address

Kinetix Fabworks Pvt Ltd.

Okkal Thuruthu.

Ernakulam – 683550.

Kerala, India.

Asia Pacific Regional Sales Support

North American Regional Sales Support

- © Copyright 2025 Kinetix fabworks Private Limited